E-Grind forniture di tutta la gamma di PCD spazi vuoti E PCDN spazi vuoti per utensili da taglio scopo. Il più grande Diametro diPCD spazi vuoti ePCDN spazi vuotiDisponibile può essere 55 millimetri. Il nostroPCD spazi vuoti ePCDN spazi vuotiFornire ad alta capacità di resistenza all'usura e di alta finitura superficiale.

Il nostro impianto installa macchine da taglio laser e macchine lappatura e finitura di superficie per fornire un servizio completo per PCD. Con avanzate di controllo macchine di SEM, C-SCAN, X-Ray Diffractometer ecc. Il nostro impianto si applica rigoroso processo di Controllo di Qualità.

Non-ferrosi metalli e leghe: Alluminio/grigio ferro composito, rame, Alluminio,...

Materiali non metallici: ceramica, plastica, gomma, truciolare...

| Prodotto | Diamante Contenuto (Vol %) | Caratteristiche del prodotto | Applicazione | |||

| ET02 | ≥ 92 | Lavorazione molto buona scarica elettrica, la vita in generale, una migliore resistenza al calore e resistenza agli urti. | Superfinishing, eccellente trattamento di superficie di qualità per il rame, bronzo, alluminio, magnesio, magnesio in lega di alluminio, di plastica, metalli preziosi, ecc. | |||

| ET05 | ≥ 92 | Lavorazione molto buona scarica elettrica, la vita in generale, una migliore resistenza al calore e resistenza agli urti. | Superfinishing, eccellente trattamento di superficie di qualità per il rame, bronzo, alluminio, magnesio, magnesio in lega di alluminio, plastica, plexiglass, ecc. | |||

| ET10 | ≥ 95 | Lavorazione di buona scarica elettrica, lunga vita, una migliore resistenza al calore e resistenza agli urti. | Fine lavorazione, qualità di lavorazione molto buona superficie, per la lega di alluminio (Si contenuto <12%), lega di rame, composito per la lavorazione del legno, di alta precisione di usura-resistente corbelled dispositivo, ecc. | |||

| ET25 | ≥ 95 | Lavorazione di buona scarica elettrica, lunga vita, una migliore resistenza al calore e resistenza agli urti. | Utilizzato per i compositi, pavimenti in laminato, non metallici materiali duri e fragili, in metallo duro della lega, grafite e grafite materiali compositi, lega di alluminio e silicio (Si contenuto> 12%), gli altri materiali di alta usura-resistente, come la ceramica, metallo duro, ecc. | |||

| ET35 | ≥ 95 | Lavorazione di buona scarica elettrica, molto lunga vita, buona resistenza al calore e resistenza agli urti. | Utilizzato per la resina, materiali compositi, materie plastiche rinforzate in fibra, ad alta densità rinforzato bordo, del silicone di materiali in lega di alluminio e altri ad alta usura-resistente. | |||

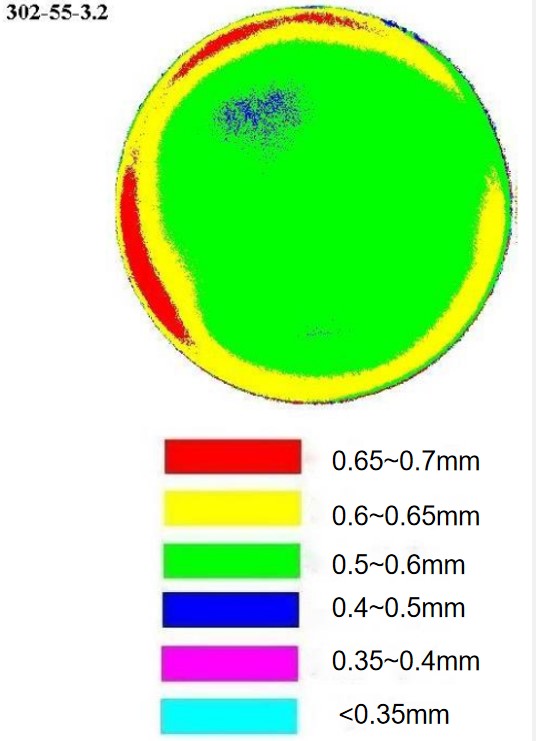

| ET302 | ≥ 95 | Lavorazione di buona scarica elettrica, lunga vita, una migliore resistenza al calore e resistenza agli urti. | Utilizzato per i compositi, pavimenti in laminato, non metallici materiali duri e fragili, in metallo duro della lega, grafite e grafite materiali compositi, lega di alluminio e silicio (Si contenuto> 12%), gli altri materiali di alta usura-resistente, come la ceramica, metallo duro, ecc. | |||

| Grano size | Applicazione | Grado | Diametro | Spessore totale | Tabella di controllo di diamante di spessore | La lavorazione del legno | Lavorazione dei metalli | Conduttivo |

| 0.85μm | Ultra-sottile struttura micron per un eccellente finitura superficiale requisiti, | ET085 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

|||

| 2μm | Per una buona finitura superficiale | ET02 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 |

|

|

√ | |||

| 5μm | ET05 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ | |

| 10μm | Di uso generale, equilibrio efficienza di taglio e la vita | ET10 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 25μm | Buona resistenza all'usura di produzione, per alta Si % in lega di Al. | ET25 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 302μm | ET302 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ | |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 35μm | ET35 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

PCBN è costituito da CBN e Legante. Si è prodotto in ad alta pressione e ad alta temperatura. Ha ottime prestazioni in durezza, elevata resistenza all'usura, stabilità termica.

Applicazione: per hard materiali ferrosi (temprato l'acciaio, ghisa, acciaio, ad alta temperatura lega, HSS, metallurgia delle polveri di metalli, Ni-Cr lega di...

E-Grind fornisce due serie di PCBN:

1) solido CBN

2) CBN con Carburo di Tungsteno di supporto.

PCBN e SBN Grado

| Grado | CBN grit (micron) | CBN contenuto (Vol %) | Modo di elaborazione | Applicazione |

| SBN95Z1 PCBN95Z1 | 20 、 30 | 0.95 | Taglio continuo con grande magazzino di rimozione | Per la pelle Ruvida trasformazione Grigio Ghisa, Refrigerati Cast di Ferro, Polvere di Lega di Sinterizzato. |

| SBN90Z PCBN90Z | 10 、 15 | 0.9 | Taglio continuo con grande magazzino di rimozione | Per la pelle Ruvida processo e semi-lavorazione di finitura il resistente all'usura ghisa ghisa grigia, ghisa sferoidale, ecc. |

| SBN90Z2 PCBN90Z2 | 10 、 15 | 0.9 | Taglio continuo con grande magazzino di rimozione | Per la pelle ruvida trasformazione e semi-di elaborazione in lega di ghisa, di alta nichel Cromo, alta cromo ferro e acciaio refrigerati con durezza HRC45-50. |

| SBN80G | 3 、 5 | 0.8 | Taglio continuo con Medio magazzino di rimozione | Per la pelle ruvida trasformazione e semi-di elaborazione in lega di ghisa, di alta nichel Cromo, alta cromo ferro e acciaio refrigerati con durezza HRC45-50. |

| SBN70G PCBN70G | 3 、 5 | 0.7 | Taglio continuo con piccolo magazzino di rimozione | Trasporto libero per la finitura il refrigerati in acciaio e lega ad alta temperatura con HRC45-55. |

| SBN60G | 1 、 3 | 0.6 | Taglio continuo con piccolo magazzino di rimozione | Trasporto libero per la finitura e super-finitura il acciaio refrigerati con HRC55-62 come portante in acciaio, acciaio per utensili, acciaio della muffa, scala in acciaio e HSS. |

| SBN55G1 PCBN55G1 | 1 、 3 | 0.55 | Lieve non-continuo e taglio continuo con piccolo magazzino di rimozione | Trasporto libero per la Finitura e super-finitura il acciaio refrigerati con HRC55-65, come portante in acciaio, acciaio per utensili, acciaio della muffa, scala in acciaio e HSS. |

| SPEC | D (Diametro) (mm) | T (Spessore)(mm) | T (spessore della sezione CBN)(mm) | PCBN55G1 | PCBN70G | PCBN90Z | PCBN90Z2 | PCBN95Z1 |

| Ф45 × 1.2 × 0.6 | 45 | 1.2 ± 0.05 | 0.5-0.8 | √ | √ | √ | √ | √ |

| Ф45 × 1.6 × 1.0 | 45 | 1.6 ± 0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 3.2 × 1.0 | 45 | 3.2 ± 0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 3.8 × 1.0 | 45 | 3.8 ± 0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 4.5 × 1.0 | 45 | 4.5 ± 0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

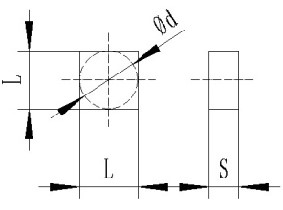

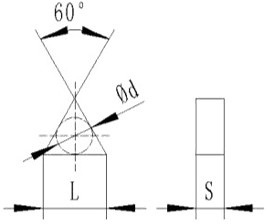

| Spec | Dimensioni (mm) | ISO | Codice | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9.85 × 3.4 | 9.85 | 9.85 | 3.4 | SNMN090300 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 5 | 9.85 | 9.85 | 5 | SNMN090400 | √ | √ | √ | √ | √ | √ | √ |

| 13 × 5 | 13 | 13 | 5 | SNMN120400 | √ | √ | √ | √ | √ | √ | √ |

| 16.2 × 8.2 | 16.2 | 16.2 | 8.2 | SNMN150700 | √ | √ | √ | √ | √ | √ | √ |

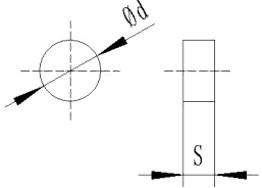

| Spec | Dimensioni (mm) |

|

ISO | Codice | |||||||

|

|

Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 6.7 × 5 |

|

6.7 | 5 | RNMN060400 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 3.4 |

|

9.85 | 3.4 | RNMN090300 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 5 |

|

9.85 | 5 | RNMN090400 | √ | √ | √ | √ | √ | √ | √ |

| 13 × 5 |

|

13 | 5 | RNMN120400 | √ | √ | √ | √ | √ | √ | √ |

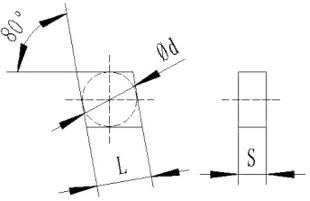

| Spec | Dimensioni (mm) | ISO | Codice | |||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | ||

| 9.85 × 5 | 9.85 | 9.85 | 5 | CNMN090400 | √ | √ | √ | √ | √ | √ |

| 13 × 5 | 13 | 13 | 5 | CNMN120400 | √ | √ | √ | √ | √ | √ |

| 13 × 8.2 | 13 | 13 | 8.2 | CNMN120800 | √ | √ | √ | √ | √ | √ |

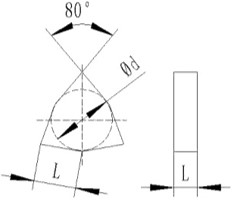

| Spec | Dimensioni (mm) | ISO | Codice | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3 × 3.4 | 11.3 | 6.524 | 3.4 | TNGN110300 | √ | √ | √ | √ | √ | √ | √ |

| 16.8 × 5 | 16.8 | 9.699 | 5 | TNGN160400 | √ | √ | √ | √ | √ | √ | √ |

| Spec | Dimensioni (mm) | ISO | Codice | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9 × 5 | 9 | 13.1 | 5 | WNMN080400 | √ | √ | √ | √ | √ | √ | √ |

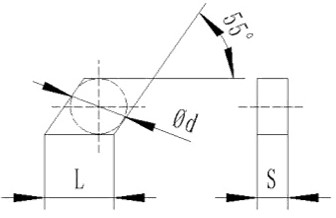

55 ° rombo

| Spec | Dimensioni (mm) | ISO | Codice | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3 × 5 | 11.3 | 9.256 | 5 | DNUN110400 | √ | √ | √ | √ | √ | √ | √ |

| 11.3 × 6.6 | 11.3 | 9.256 | 6.6 | DNUN110600 | √ | √ | √ | √ | √ | √ | √ |

| 15.8 × 6.6 | 15.8 | 12.943 | 6.6 | DNUN150600 | √ | √ | √ | √ | √ | √ | √ |